No, 88/12 refers to only the content of the raw material before any FR engineering; it does not tell you anything about the FR process, properties or durability of the final fabric. You should know what fabric brand is in your garment and be very cautious if the only information provided is “88/12”.

Fabric sold as “88/12” can be non-FR, it can be FR that lasts only until it gets wet, it can be FR for up to a hundred washes or it can be FR for the life of the garment. Don’t rely on this one-word designation; specify a brand, not a category.

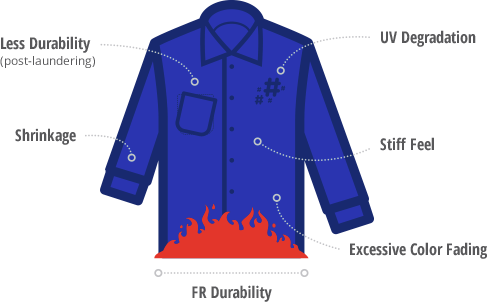

Performance qualities of FR fabrics such as durability of the flame resistance, protection, comfort, shrinkage, breathability, softness and durability vary significantly between fabric brands. Be sure you evaluate the different FR fabric options first and then specify to your provider which FR fabric brand you need.

Westex: A Milliken Brand uses proprietary state-of-the-art processes to engineer flame-resistant fabrics:

- Our proprietary multi-step FR process ensures much deeper penetration and distribution of the FR polymer into the cotton structure.

- Our proprietary advanced fabric softening process involves a unique balance of chemical and mechanical procedures. This advanced technology dramatically improves softness and comfort.

- Our proprietary shrinkage technology preshrinks fabric which allows for greater long term shrinkage control.