Westex and PES: Leading the Charge in Arc Flash Safety with New OSHA Guidelines

Today, we continue to lead in protecting workers by staying ahead of safety standards and technological advancements.

Read more

Today, we continue to lead in protecting workers by staying ahead of safety standards and technological advancements.

Read more

Visibility isn’t just a convenience—it’s a lifesaver. Whether you’re a construction worker, utility technician, police officer, paramedic, or firefighter, being seen by your colleagues and bystanders can mean the difference between safety and disaster.

Read more

Project Details Lummus Technology Pasadena, TX 110 employees in FR apparel Daily Wear program provided by an industrial launderer Step 1: Identifying the Problem Lummus Technology faced a significant challenge—their long-used Flame Resistant gear was so uncomfortable that it posed a health risk. With the blistering Texas heat reaching 100°F...

Read more

Layering FR apparel is a highly effective strategy for maximizing protection against arc flash incidents. Here’s why layering matters:

Read more

Electric vehicles (EVs) are revolutionizing transportation, but with this innovation comes new safety challenges – especially for professionals installing vehicle charging stations.

Read moreDuring August and September, our team was proud to attend two tradeshows alongside industry partners focused on safety. Showcasing Westex®, a Milliken brand, our associates highlighted how our FR/AR fabrics empower safety professionals to protect their workers every day.

Read moreLast month, Westex®: A Milliken Brand hosted safety professionals from many US-based oil and gas companies for a one-day educational event featuring a live flash fire demonstration.

Read more

Developing flame-resistant, arc-rated (FR/AR) fabrics that prioritize safety and adhere to sustainable practices is a priority for the FR/AR market. This connection comes down to key touchpoints: material sourcing, fabric manufacturing, and garment lifecycle.

Read more

Flame-resistant (FR), arc-rated (AR) apparel is critical when there’s a risk of electric arc flash, a gas/vapor/combustible dust fueled flash fire, or molten metal splash exposure.

Read more

Interview with Kelly Franko, owner of Seraphina Safety Apparel

Read more

While the pursuit of progress is relentless in the utility, oil and gas, industrial, and alternative energy sectors. It’s essentially to understand the importance of daily wear PPE for errors with high human fallibility.

Read more

Kicking off a new year presents various opportunities for change and improvement. One simple way to reach your target? Ensuring your electrical safety PPE programs are aligned with the 2024 NFPA 70E standard.

Read more

Currently, there is significant demand for innovation in the PPE market. As industries evolve and complex challenges arise, we must push the boundaries of conventional solutions.

Read more

The Westex team was thrilled to bring our newest products, latest industry insights and networking appetite to this year’s NSC Expo in New Orleans, Louisiana.

Read more

Demand for more comfortable FR/AR PPE continues to grow. At the top of many wearers’ minds is finding garments with stretch characteristics.

Read more

Well, before we decide if anything is meaningful, let’s discuss what the terms actually mean.

Read more

In the protective apparel market, safety is king. But in recent years, apparel programs have started to evaluate how to integrate sustainability into the garments that keep the hardest working industries safe on the job.

Read more

Westex is looking forward to returning to Europe’s A+A safety expo this autumn. As the world’s leading trade fair for safety and health at work, this biennial show will be hosted in Düsseldorf, Germany from 24–27 October.

Read more

Westex is proud to announce that as part of Milliken & Company, it is committed to working toward meeting the science-based targets in line with the Science-Based Targets initiative (SBTi) for reducing its greenhouse gas (GHG) emissions.

Read more

How do you prioritise comfort versus protection in hot conditions when it comes to the clothing you and your employees wear in typical, yet potentially dangerous, situations?

Read more

In a recent webinar with Scott Francis, Technical Sales Manager, we discussed the key drivers of flame-resistant and arc-rated (FR/AR) fabric technology.

Read more

Jeff Strahan, Ph.D., our Director of Research, Compliance and Sustainability, shared three key factors of sustainable manufacturing that companies everywhere need to keep in mind in a recent webinar. If you missed it, here’s a quick recap.

Read more

Westex visited ASSP’s signature tradeshow this year, Safety 2023 in San Antonio, TX, to show the latest from our product development team, share updates on our current initiatives, meet with our customers and interact with visitors from across the country.

Read more

FR vs. AR—two incredibly important terms with distinct roles that sound far too similar to leave unexplained. Let’s talk about how they’re different and why that impacts the decisions you make in protecting your team.

Read more

When we say that our flame-resistant and arc-rated (FR/AR) garments are “proven,” take more than our word for it. Trust the quality checks. Trust the certifications. Trust rounds and rounds of comprehensive testing procedures—all performed more often than required.

Read more

It’s been said that offense wins games, but defense wins championships. Selecting protective gear that defends your workers in a complex market full of standards is difficult—so we’re creating an easy-to-learn logic to help you and your employees stay protected.

Read more

We recognize your need for the on-time delivery of sustainable, high-quality products, and we’re always willing to roll up our sleeves and put in the work to deliver on what you care about most.

Read more

Complacency on a job site is usually unintentional, but it always carries a risk. When workers who are supposed to be outfitted with flame-resistant/arc-rated personal protective equipment (FR/AR PPE) become complacent and allow errors, the risk may turn into a life-threatening situation.

Read more

Let’s explore three ways Westex®: A Milliken Brand fabrics are helping to create a more sustainable future, with connections between proven flame-resistant/arc-rated (FR/AR) fabrics and steam, renewable wood, and even 53,000 gallons of water.

Read more

Given the regulatory activity surrounding PFAS, it is becoming increasingly clear that the FR/AR textile and garment industries will have to adapt because FR/AR garments are vital – and in many instances, mandatory – to protect workers in hazardous workplace environments.

Read more![“one size [does not] fit all”: the evolution of women’s ppe](https://webapi.westex.com/uploads/WX_blog_V5_7eeedefff1.jpeg)

How do we alter flame-resistant/arc-rated (FR/AR) garment programs to suit women?

Read more

Partnership offers environmentally-focused FR textiles, marketing program

Read more

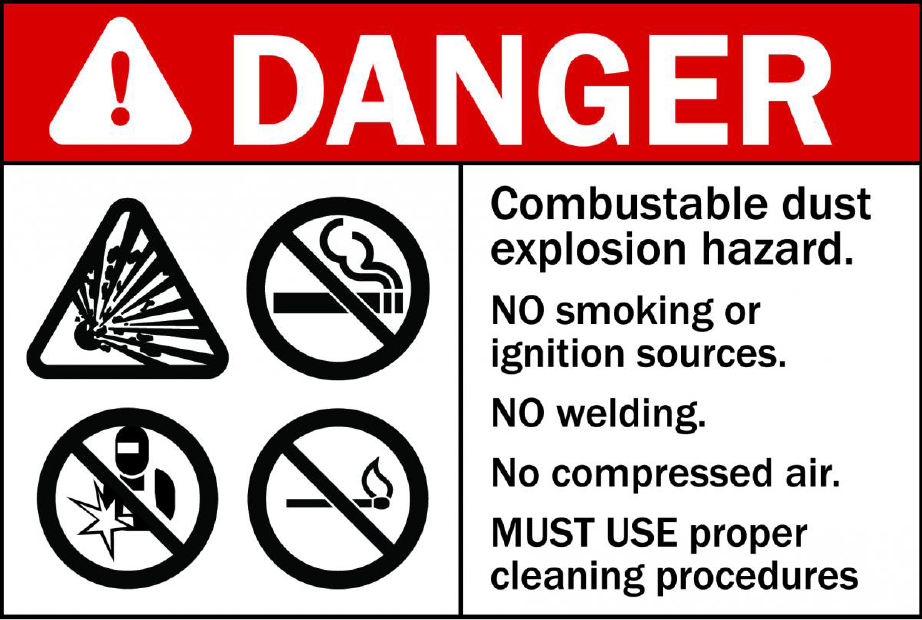

Amid today’s workplace safety landscape, combustible dust is a conundrum. Dust in the workplace is unavoidable; yet, managing dust is much more than a routine housekeeping consideration. Anything from sugar to metal to rubber can produce dust, and in manufacturing settings, these dust particles can pose serious hazard risks. These...

Read more

Safety managers are constantly analyzing their site risks to create the safest possible environment for their workers. Especially when considering short-term thermal events, like arc flashes or flash fires, stacking the deck with proactive and reactive measures are critical in mitigating injuries. Burn injuries are one of the primary considerations...

Read more

This fall, the Westex: A Milliken Brand team is excited to return to the annual NSC Safety Congress and Expo, hosted this year in Orlando, FL, October 11-13. The event — a key safety industry convening for more than 100 years — brings together professionals to focus on industry-leading safety...

Read more

As we all adjust to a new normal in the era of COVID-19, safety is more essential than ever. This month, the Westex team will travel to Austin, TX, to participate in ASSP Safety 2021—a major professional conference bringing together the safety industry. From September 13-15, Westex: A Milliken Brand...

Read more

NFPA® 70E provides a system of checks and balances to account for electrical hazard safety on your job site. The hierarchy of risk controls provides safety managers and employers a host of administrative and engineering tools to help prevent arc flash incidents and mitigate injuries should an incident occur. Because...

Read more

If you’ve been involved in the oil & gas, electrical, or industrial manufacturing industries, chances are you’re familiar with personal protective equipment—PPE for short. PPE plays a critical role in protecting workers who face any number of job site hazards, from combustible dust, flash fire and arc flash incidents to...

Read more

Setting the tone for the latest edition, the 2021 NFPA® 70E® Standard cover prominently features the hierarchy of risk controls, first introduced in the 2018 edition. Recommitting and reemphasizing the importance of the hierarchy of risk controls, the cover—and the standard as a whole—draws attention to this tool, which...

Read more

Are you a March Madness fan? Chances are, you’ve never contemplated the similarities between zone defense of your favorite basketball team and the “defense” that flame-resistant (FR)/arc-rated (AR) PPE plays in mitigating thermal hazard risks in workplace settings. In either case, solid zone defense and FR/AR PPE do more...

Read more

Westex Launches Mobile App to Streamline FR/AR Product Selection Process The first-to-market tool matches products to global safety standards SPARTANBURG, SC (Feb. 9, 2021)—Westex: A Milliken Brand, announced today the launch of a new product selection app, the Westex App, developed to provide users a way to custom build a...

Read more

Westex and Polartec Debut Polartec Flame Resistant Collection Two category leaders collaborate to produce flame resistant/arc-rated knits certified for the job with overtime comfort. SPARTANBURG, S.C. — Two Milliken & Company textile businesses—Westex®, a leader in dual-hazard protective textiles, and Polartec®, the premium provider of innovative and sustainable textile solutions—announce...

Read moreThose who work in the industrial environment face multiple threats. In this instance, we’ll focus on intense electric-related hazards, specifically electric arcs. During an electric arc, temperatures can reach up to 35,000°F, or 20.000°C (that’s hotter than the surface of the sun), so wearing the...

Read moreIf you’ve been waiting to complete a few of the bigger tasks on your agenda, use this season to do some much-needed spring cleaning—especially if your facility faces combustible dust hazards. Per the NFPA® 652 Standard on the Fundamentals of Combustible Dust (2019), you’re required to complete a Dust Hazard...

Read moreWe’re passionate about educating the electrical industry on safety standards that address short-term thermal hazards, like arc flash and flash fire. It’s how we know we’re helping equip you with not only the industry’s leading flame resistant/arc-rated (FR/AR) textiles for personal protective equipment (PPE), but also helping apply these methods...

Read moreThroughout the electrical industry, consensus standards provide critical information advising how to safeguard employees facing arc flash hazards. These standards—NEC, NESC, and NFPA 70E—are all meant to guide safety initiatives, but which one is relevant for you? We break down each standard and what they mean for your workplace....

Read moreCombustible dust is a significant concern across various industries and with good reason. Combustible dust incidents can lead to serious property damage and cause life-threatening injuries. Analyzing your work environment and enacting preventative measures, such as robust housekeeping and engineering control protocols, can make all the difference. Even with these...

Read moreWhile properly wearing flame resistant (FR), arc-rated (AR) personal protective equipment (PPE) helps protect employees facing arc flash and short duration thermal exposures from fire, like flash fires, it is equally important to clean and maintain these protective garments. Proper care practices help ensure a PPE garment’s safety properties remain...

Read moreThe FR industry certainly has its share of jargon, and especially when that jargon has little scientific background, it can lead to muddled and complicated decisions. In our white paper, What’s in a Word: Inherent Fabric, Treated Fabric, and What They Mean in the World of Flame Resistant Fabrics, we...

Read moreFlame resistant (FR), arc-rated (AR) personal protective equipment (PPE) is an important part of establishing a well-rounded safety program. Before donning their FR/AR PPE, however, employees need to be educated about their PPE garments so they can properly guard themselves against workplace hazards such as arc flashes or flash fires....

Read morePart of designing reputable protective fabrics is ensuring they provide certified, consistent results both in the lab and in the field—otherwise, end users may be at risk. Flame resistant (FR), arc-rated (AR) fabrics incorporated into personal protective equipment (PPE) act as a final layer of defense against hazards like arc...

Read moreWhen we look to develop new flame resistant (FR) technologies, we often draw inspiration from unmet needs in the industry. Many times, our conversations in the field help us better identify areas where we can fill a gap to better protect workers in the electrical and oil and gas industries...

Read moreUntil recently, flame resistant (FR), arc-rated (AR) garments were one size fits all—meaning both men and women wore the same styles. Women in the oil and gas and electrical industries thus donned ill-fitting FR/AR garments day in and day out, because these garments were largely constructed with men in mind....

Read moreFor worksites where short-term thermal hazards are present, flame resistant (FR), arc-rated (AR) personal protective equipment (PPE) is a critical component in providing protection in the event of an unexpected incident, like arc flash, flash fire, or dust combustion. While key, however, it is important to note that when designing...

Read moreDrawing from customer feedback and suggestions, the Westex® DH line of performance flame resistant (FR), arc rated (AR) fabrics was created to meet the most requested and pressing end-user needs for thermal hazard FR/AR personal protective equipment (PPE). Durable and robust, the line offers superior arc flash and flash fire...

Read moreCollaboration is key for discovering creative and sustainable solutions to meet customers’ needs. To that end, we are excited to share our successful collaboration with Cone Denim - leaders in premium denim for consumer apparel - will be renewed to continue offering our customers cutting-edge arc rated (AR) flame resistant...

Read moreDecades of expertise and a deep understanding of the science of a flame go into creating new arc rated (AR) and flame resistant (FR) fabrics. We sat down with Drew Child, Director of Technology and Program Director for Milliken’s Uniform and Protective Fabrics Business, to discover more about the process...

Read moreThere are many factors that go into creating a high-quality FR fabric. While there are many flame resistant (FR) properties that are often mentioned, such as durability and industry certifications, there are some characteristics that tend to receive less attention. We rounded up five interesting facts that you may not...

Read moreJune 26, 2019, Greensboro, N.C. – Two industry powerhouses Cone Denim® and Westex by Milliken, the flame resistant (FR) textiles business of global manufacturer Milliken & Company, are pleased to announce they have extended their exclusive partnership to provide innovative flame resistant denim apparel fabrics for the industrial workwear market...

Read moreWhile the aluminum industry can generally be a safe place to work, there are occupational hazards that employees need to be aware of and actively guard themselves against. It is important for safety managers to fully assess the workplace for the risk of potential short-term thermal hazards and design a...

Read moreHeat stress can be a serious concern year round, but it is especially prevalent in the warmer summer months. There are many factors that contribute to an increased risk of heat stress including high external temperature, humidity levels, sun exposure, lack of breeze, not drinking enough water, intensity of labor,...

Read moreHeadquartered in Andover, Massachusetts, the Polartec brand carries a respected portfolio of fabric technologies for outdoor apparel, from performance-driven and consumer-focused textiles, to flame-resistant, workwear and military-grade fabrics. The addition of the Polartec brand—particularly its outdoor and fleece textiles—rounds out Milliken’s comprehensive portfolio, allowing the company to deliver unprecedented access...

Read moreSPARTANBURG, S.C. – Westex by Milliken, an industry-leading arc-rated (AR) flame-resistant (FR) textiles manufacturer, will present its line of protective textiles at ASSP Safety 2019 in New Orleans, Louisiana, June 9-12. As a Milliken & Company business, Westex by Milliken builds on the trusted fabric brand by incorporating its parent...

Read moreEvery year, safety professionals, manufacturers and more gather at ASSP Safety to attend educational seminars, review best practices, discuss industry trends and find the latest innovations in safety. Westex by Milliken is a regular exhibitor, and we always enjoy connecting with others who have the same mission we do: to...

Read moreMay is Electrical Safety Month, which is a good reminder to ensure your team’s safety efforts are in line with the updated industry consensus standard NFPA 70E. Workers in the electrical field are exposed to unexpected hazards, including arc flashes, so safety precautions should be reviewed frequently to help reduce...

Read more

Safety managers have a very important decision to make when determining the type of personal protective equipment (PPE) that their team needs. Before nailing down the fabric, apparel and PPE brands they would like to select, they first need to determine whether their team, or even specific members of their...

Read more

It is every employer’s goal to keep its workers safe on the job, but providing for the safety of your employees requires a holistic approach. Forming just one dimension of a hazard mitigation program, personal protective equipment (PPE) can be extremely beneficial when specified correctly. It is important, though, to...

Read more

When the 2018 edition of NFPA 70E went into effect, many within the industry took time to explore how the standard changes would affect both employers and workers. There are a number of articles you can turn to on the subject; indeed, even Westex by Milliken has penned a few...

Read more

In our line of work, it is critical to understand the needs of our customers. From the nature of the daily hazards you face to the ever-important subject of budgets, Westex by Milliken understands that a number of factors go into selecting the right arc-rated/flame resistant (AR/FR) fabric for a...

Read more

Unexpected arc flash and short-duration thermal exposure from fire hazards, also known as flash fire, are a daily reality for electric utility and oil and gas workers. To help keep workers safe on the job, industrial personnel require ongoing hazard protection in addition to specific attire for certain tasks. Everyday...

Read more

Flash fires and fuel-fed fires are different, and it's critical to distinguish between the two for various safety reasons. The potential exists for flash fires in the oil and gas industry. Flash fires are sudden, intense fires caused by ignition of flammable substances in air. While flash fires cannot be...

Read more

Workers in utility and oil and gas industries have specific needs for high-visibility and FR protection on the job. They operate in areas with large amounts of electrically charged equipment and flammable materials, often during nighttime and in complex settings. While the need for FR PPE in these lines of...

Read more

For those in the oil & gas industry, flash fires are a prevalent risk throughout the upstream and downstream lines. The flammability of oil, as well as the extraction and refinement processes, requires thoughtful personal protective equipment (PPE) selection, so that workers are protected on the job. With the updates...

Read more

Back in the fall, NFPA 2112: Standard on Flame-Resistant Clothing for Protection of Industrial Personnel Against Short-Duration Thermal Exposures from Fire saw new changes implemented for the 2018 edition, which went into effect on September 6, 2017. The 2018 edition is a barometer for the safety industry as a whole...

Read more

Know what you are truly buying: The flame resistant, arc rated (FR/AR) fabric in workwear is the single largest factor in determining the garment’s protection level, comfort, and overall value. Every day, workers in electrical maintenance, utility, oil and gas, petrochemical, and steel industries work in hazardous environments. Unexpected and...

Read more

The updated NFPA 70E can be explored through the lens of parties impacted. Through analyzing party responsibility, safety engineers and managers can make informed decisions to comply. As an industry standard, NFPA 70E outlines elements of an electrical safety program to protect workers from high-risk electrical hazards they come into...

Read more

Electrical workers face the risk of unexpected arc flash incidents throughout their daily operations by the very nature of their job. The right apparel can offer protection and peace of mind. When arc flashes occur, the most severe injuries often are the result of non-flame-resistant clothing igniting and continuing to...

Read more

After surviving an arc flash accident, which landed him in the hospital and required an extensive recovery process, Brandon Schroeder keenly felt the value in sharing his story. Not only was it a poignant narrative, but it also drove home the fact that an arc flash accident impacts more than...

Read moreToday’s #70EChat, hosted by NECA and Westex by Milliken, brought the electrical industry together to discuss the ever-evolving world of electrical safety. Exploring the 2018 edition of NFPA 70E – and more importantly, what that means for electrical contractors – the #70EChat raised important questions, offered new perspectives, and opened...

Read more

When a work environment is safe, workers are free to focus on their jobs. That is the driving belief behind Milliken’s commitment to safety. We are happy to announce that Milliken & Company has been included in America’s Safest Companies List. Created in 2002, American’s Safest Companies is a corporate...

Read more

As any safety manager will tell you, understanding hazards is as important as identifying them. Through understanding, you can appropriately plan for and mitigate job worksite hazards in order to build a safety program that successfully protects your employees. Recently, Westex by Milliken hosted a one-day educational session to help...

Read more

Last month, Westex by Milliken joined the industry in one of the largest safety conferences in the U.S. – NSC Congress & Expo. It is an opportunity to be immersed in the industry - gleaning information, learning the latest developments and experiencing products in-person. For us, it is also an...

Read moreThe vast number of flame resistant fabrics, garments and manufacturers in today’s market has led to confusion around the differences between flame resistant (FR) fabric types, FR fabric manufacturing methods and FR garment brands. Many don’t realize that the term “88/12 FR” is nothing more than a fabric content or...

Read more

When Dan joined an American company as Environmental Health and Safety Manager, his team leader and Director of Environmental Health and Safety, Robin, immediately informed him that the field employees, had a high exposure to arc flash over the course of their daily operations. The company’s 1,500 field technicians interact...

Read moreLast year, a Los Angeles County jury found Qualcomm liable for $7.1 million[1] in damages as a result of a burn incident. Qualcomm, a telecommunications equipment company, was found negligent in an electrical fire incident, where a third-party contractor suffered third-degree burns while servicing electrical equipment on the company’s premise....

Read more

By Matt Burtney Content Marketing Associate, Superior Glove and Scott Francis Midwest Regional Market Manager, Westex by Milliken Embracing a Safety Culture: Since 1970, the workforce in the United States has doubled. In that same time, on-the-job fatalities have fallen by 68%. What’s the driving force behind this change? Promoting...

Read more

By Scott Francis Midwest Regional Market Manager, Westex by Milliken and Samantha Hoch Marketing Communications Strategist, Haws® We believe when it comes to safety, you should not have to compromise. Leaders in the safety industry design innovative, yet functional, equipment to protect workers while on the job. From emergency response...

Read more

By Jason Reason CIH, CSP, CHMM Senior Vice President of Safety and Health Services, Lewellyn Technology, LLC with Scott Francis Midwest Regional Market Manager, Westex by Milliken The issue of combustible dust and its associated hazards (fire, deflagration, explosion) has always existed in several industries in one form or another....

Read more

A vital part of FR safety is raising awareness and education. At Westex by Milliken, we pride ourselves on being more than just an FR fabric manufacturer. We are your FR resource when it comes to navigating the complex industry of arc rated and flame resistant fabrics and protection. We...

Read more

We are excited to have wrapped up another successful American Society of Safety Professionals (ASSE) Safety show, this year in Atlanta! This trade show and exhibition brings safety professionals together to learn best practices, discuss industry updates, and make connections with suppliers and each other. Now that the show is...

Read more

In honor of National Safety Month, we’re taking a look at the importance of ongoing safety education and training. Safety excellence means going beyond recording a zero injury number to embedding safety into the culture of your workforce. After all, being safe is about employee buy-in and the employees themselves,...

Read more

“Our safety goal is zero injuries. We are committed to safety excellence in everything we do. Our basic belief is that all incidents can and will be prevented.” Charlie Young, Corporate Safety Manager at Milliken & Co. Safety is a core value at Milliken that drives our efforts to build...

Read more

Westex by Milliken is “all in” when it comes to FR education. Most companies in our industry are just suppliers; we want to be your partner in safety, and that involves bringing more to the table than a piece of fabric. We help you make good decisions about protective clothing...

Read more

Burn injuries resulting from arc flash, flash fire or combustible dust hazards can be life threatening or worse, life-ending. Both the temperature and duration of the exposure directly impact injury severity. In honor of National Electrical Safety Month, this blog post takes a look at the impact of a burn to...

Read more

The best way to enforce NFPA 70E is through company policy for your employees and customers. Companies should look at all aspects of NFPA 70E to determine what policies are needed and what policies they want to create and enforce. The purpose is to set forth procedures for the safe...

Read more

Each May the Electrical Safety Foundation International (ESFI) commemorates National Electrical Safety Month (NESM) to raise awareness and educate the public on critical electrical safety topics. EHS Today reported in 2015 that, “Workplace electrical incidents result in another nearly 300 deaths and more than 3,500 injuries every year. Although not...

Read more

Earth Day is Friday, April 22nd, an annual event to celebrate environmental protection. Did you know that 70 years before the U.S. Environmental Protection Agency (EPA) was established, Milliken & Company initiated voluntary environmental stewardship practices? In fact, today more than 99% of Milliken’s solid waste worldwide is reused, recycled...

Read more

When it comes to arc-rated and flame resistant clothing, there’s a science behind peace of mind, a science to feeling good, and a science to coming home safe. When it comes to the science of being safe, of caring, we are all in. Westex by Milliken is proud to be...

Read more

Starting later this year, a new arc flash testing laboratory in Brazil will begin testing to ASTM and IEC standards for flame resistant fabrics, garments and rainwear, face shields and gloves. Petrobras, the largest multinational energy corporation in South America, has partnered with the Energy and Environment Institute at the...

Read moreAccidents are just that, they happen by chance and not on purpose. In fact, after an accident workers are often heard saying how safe a particular electrician “always was”… until the day he or she wasn’t. Accidents where workers think energized circuits are dead claim the lives of electricians every...

Read more

For the tenth year in a row, Milliken & Company has been recognized by Ethisphere Magazine as one of the World’s Most Ethical Companies. Milliken has long understood that ethical behavior is not just the right thing to do but is a key to sustainable growth, forming the foundation of...

Read more

A qualified person is defined in various ways by different standards and depending on what industry you are in. In the electrical industry, for example, it’s important for both qualified and unqualified workers to understand and receive training for the equipment they are working on. In construction, and electrical construction...

Read more

In recent years, the combustible dust hazard has been receiving increasing attention from both OSHA and NFPA. OSHA defines combustible dusts as fine particles that present an ignition hazard when suspended in air under certain conditions. The combustible dust hazard is a flash fire event or rapid combustion known as...

Read more

The story behind our commitment: When it Comes to FR Safety, We Are All In Westex by Milliken has always provided much more than high-performance FR fabric. For decades, we’ve taken a big picture approach to FR safety. This article shows you what it means to be “all in,” with...

Read more

Safety management systems are designed to be comprehensive and manage safety elements in the workplace. A safety system is a process that continuously operates to reduce hazards and prevent workplace incidents. Safety is a critical element in any business and it’s important that all employees buy-in to the safety program....

Read more

Personal protective equipment (PPE), such as arc rated FR clothing, is a critically important part of every electrical safety program. It should be used as the last line of defense, meaning it helps protect when all other preventative measures have failed. In fact, the hierarchy of controls puts eliminating the...

Read more

Now offering an even more complete line of Westex-branded FR solutions! In September, Milliken & Company announced the acquisition of Springfield LLC, a manufacturer of technical, performance and flame resistant (FR) fabrics for the safety apparel, fire service, military and occupational markets. This acquisition is the latest initiative in Milliken’s...

Read more

Flame resistant (FR) coveralls, shirts and pants afford workers a few extra seconds of escape time when faced with a flash fire and aim to dramatically reduce or eliminate body burn. FR garments are tested according to a variety of standards. For flash fire, ASTM F1930 (Standard Test Method for...

Read moreAcquisition broadens ability to protect industrial workers, first responders and military personnel worldwide with expanded product portfolio and technical capabilities SPARTANBURG, S.C. – Today, Milliken & Company, a global innovation company, announced its acquisition of Springfield LLC, a manufacturer of technical, performance and flame resistant (FR) fabrics for the safety...

Read more

The answer to this question has been debated along with other FR marketing issues; however, groundbreaking research has been conducted to reaffirm the behavior of flash fires. Research performed by the University of Alberta’s Protective Clothing and Equipment Research Facility (PCERF) has reaffirmed the industry’s benchmark flash fire standards from...

Read more

You’ve been told you need NFPA 2112-compliant garments but do you understand what compliance actually means? NFPA 2112 is an industry standard on flame resistant garments for protection of industrial personnel against flash fire. NFPA 2112 provides minimum performance criteria and sets clear guidelines for testing. What’s vital to understand...

Read more

The challenge of keeping pace with keeping safe In today’s world, information overload makes it nearly impossible to digest all of the messages constantly being pushed at us. With a steady stream of news updates always in front of us, it can be difficult to pull out the most important...

Read more

Safety is an initiative that every organization should prioritize, and eventually turn into a value. Being safe is about employee buy-in and the employees themselves – not just about the numbers. Much like with personal protective equipment (PPE) - where you have to get employees to see the value in...

Read more

Arc flash accidents are frequently noted when, unfortunately, something terrible goes wrong and an employee is injured. However, not all of these stories end badly due to proper use of arc flash protection. In his article for Flame Resistant Insights, Larry Hilgeman of The Hilgeman Group, Inc., shares a report from...

Read more

Arc flash accidents are frequently noted when, unfortunately, something terrible goes wrong and an employee is injured. However, not all of these stories end badly due to proper use of arc flash protection. In his article for Flame Resistant Insights, Larry Hilgeman of The Hilgeman Group, Inc., shares a report from...

Read moreSPARTANBURG, S.C. – Westex by Milliken and Cone Denim announced an exclusive partnership to provide innovative flame resistant denim apparel fabrics. Both leaders within their respective industries, Cone Denim and Westex by Milliken will merge fashion with protective, reliable industrial workwear fabrics. “Cone Denim has a strong reputation of quality...

Read moreSPARTANBURG, S.C. – Westex by Milliken and Cone Denim announced an exclusive partnership to provide innovative flame resistant denim apparel fabrics. Both leaders within their respective industries, Cone Denim and Westex by Milliken will merge fashion with protective, reliable industrial workwear fabrics. “Cone Denim has a strong reputation of quality...

Read more

Westex has entered into agreement with The National Joint Apprenticeship and Training Committee for the Electrical Industry (NJATC) to create the Westex Personal Protective Equipment Academyprogram to train the next generation of union electrical workers. Over the next five years, Westex will donate $650,000 in cash, product and training support,...

Read more

Westex and the American Society of Safety Engineers (ASSE) have signed a 2-Year extension to the existing Gold Sponsorship Agreement for 2014-2015. Over the next two years, Westex will provide a financial contribution to ASSE along with product and educational support to the ASSE membership. Westex’s Gold Sponsorship of ASSE...

Read more

Historically, the flame resistant properties of flame resistant fabrics could be separated into two categories: Inherent and treated. Once upon a time, this was a relevant distinction. It meant the difference between FR properties that were durable, and those that were not. However, these terms ceased to provide information to...

Read moreThe success of your flame resistant (FR) clothing program depends heavily on the fabric used to construct the garments. Both arc rating and flash fire “2112” testing are done by fabric brand and weight; the fabric brand is also the key factor in durability of FR properties, initial and long...

Read more

Westex TrueComfortTM is a new advancement in flame resistant knit fabrics. The new TrueComfortTM fabrics are lightweight, soft and breathable, and offer the same guarantee of flame resistance for the life of the garment as Westex’s proven UltraSoft®, UltraSoft AC® and Indura® brands. In addition, TrueComfortTM provides excellent arc flash protection...

Read moreView who The Institute for Safety and Health Management selected for its 2013 Safety Management Professional of the Year. 2013 Safety Management Professional of the Year

Read moreThere are many questions and even more misunderstandings around comfort and heat stress for people specifying or wearing arc rated and flame resistant protective apparel; thus, it is important to understand a few basics on the interrelationship, if any, to garment or fabric type and weight. Discomfort and heat stress...

Read moreOver the past two decades, there has been reasonable debate (and less reasonable marketing) on the duration and energy of flash fires. Westex’s Technical Director Scott Margolin explores the complexities of this hazard and the testing methods commonly used to evaluate FR clothing. Read the article now.

Read moreWestex has published a new white paper designed to clarify the difference between “inherent” and “treated” flame resistant fabrics. The paper explains: The origins of these terms How they became part of the industry lexicon –– in spite of having no scientific basis Why these categories aren’t useful for evaluating...

Read moreWritten by Westex International Technical Director Scott Margolin, this must-read article addresses the importance of fabric wear tests, and explores comfort factors such as breathability and weight. Read the full article on the Occupational Health & Safety (OH&S) site.

Read moreWestex is the only company in the industry with the technology and expertise to consistently produce FR fabrics with the qualities that matter: Guaranteed flame resistance for the life of the garment Double-shrunk technology Superior softness That’s not a claim — it’s a fact. See for yourself by viewing the...

Read more